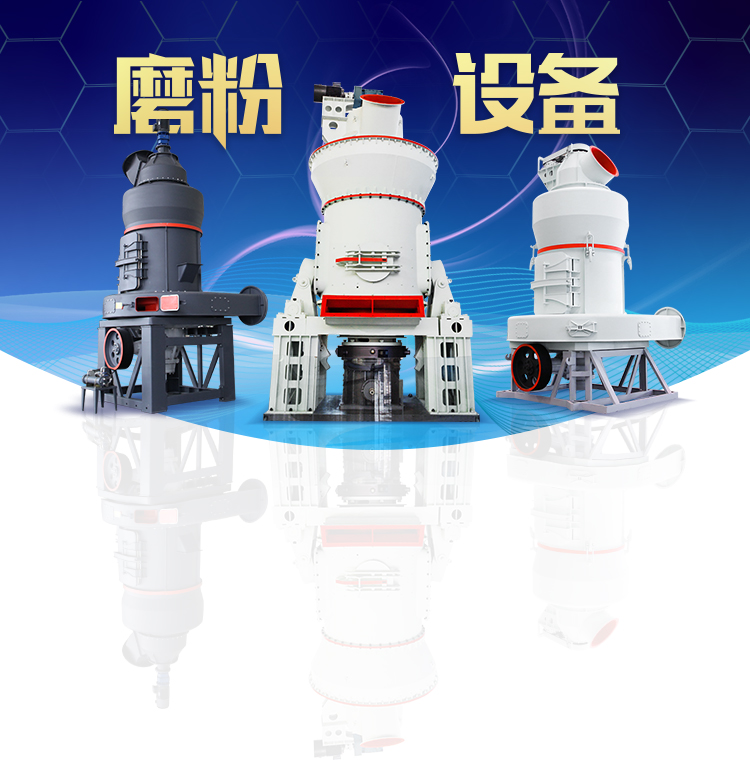

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

250 Um Or Less Using A Ball Mill Eg S石灰石x Industries 8000

A Review of the Grinding Media in Ball Mills for Mineral

2023年10月27日 Grinding media play an important role in the comminution of mineral ores in these mills This work reviews the application of balls in mineral processing as a function of the 2017年9月1日 The use of this shape classification system clarifies that the lessrounded distribution for the ball mill ultrafine sample is due to the particles being more elongated rather Fine grinding: How mill type affects particle shape characteristics 2014年3月1日 With a view to developing a sound basis for the design and scaleup of ball mills, a large amount of data available in the literature were analyzed for variation of the two key mill(PDF) Analysis of ball mill grinding operation using mill power 2018年6月1日 In this article the effect of grinding media size distribution and feed material particle size distribution (PSD) on the product fineness requirements were investigated A Effect of ball and feed particle size distribution on the milling

.jpg)

(PDF) Grinding in Ball Mills: Modeling and Process Control

2012年6月1日 The paper presents an overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills Basic kinetic and energy Explain the role of ball mill in mineral industry and why it is extensively used Describe different types of ball mill design Describe the components of ball mill Explain their understanding of ball mill operation Explain the role of critical AMIT 135: Lesson 7 Ball Mills Circuits – Mining 2021年8月1日 Ball mills are one of the most common industrial equipments for reducing the size of particulate systems in various fields such as cement industry, minerals or nuclear fuel Investigating grinding mechanisms and scaling criteria in a ball mill 2024年8月8日 Unlock the secrets to ball mill efficiency with our comprehensive guide on choosing the right grinding media Learn how material composition, size, shape, hardness, and cost impact your milling process and outcomes Perfect Ball Mill Success: A StepbyStep Guide to

.jpg)

Estimation of the Specific Energy Requirement for Size Reduction

2016年11月8日 Design engineers generally use Bond Work Index and Bond energy equation to estimate specific energy requirements for ball milling operations Morrell has proposed 2024年9月24日 The Bond Ball Mill Grindability Test (Bond, 1952, 1961) gives the Bond Ball Mill Work Index This Index expresses the resistance of a material to ball milling; the higher the Why is the Bond Ball Mill Grindability Test done the way 2012年12月15日 Ball milling is a method of production of nano materials This process is used in producing metallic and ceramic nano materials These mills are equipped with grinding media composed of wolfram carbide or steel Ball mills Nano Ball Milling PPT Free Download2 天之前 12503732424 Get our new mobile app today: Connect with us: 8,000 Horsepower; 10,000+ Horsepower; Motor Bases; New Surplus Electrical Motors; Single Phase Nordberg 11' x 26' Ball Mill Make: Nordberg Size: 11ft New and Used Ball Mills for Sale Ball Mill Supplier Worldwide

The Ultimate Guide to Ball Mills Miningpedia

2019年8月14日 The replacement of the ball mill liner is a very cumber some and technically highquality work In addition to the above mentioned replacement techniques, the personal safety of the staff is particularly needed Correct ball mill liner replacement operation can improve the use time of the ball mill and ensure the safe operation of the ball mill2024年9月24日 the rotating charge inside most industrial ball mills Most industrial ball mills have lifters Data from 40 ball mills show that the average critical speed is 073 (Morrell, 1996) Research in mill charge motion (eg Mishra and Rajamani, 1992; Inoue and Okaya, 1994) reveals how the charge motion vary with mill speed and liner/lifter profileWhy is the Bond Ball Mill Grindability Test done the way 3 天之前 Standard mills are furnished with liners to avoid replacement of the shell; however, the mill can be obtained less liners This ball mill is often driven by belts placed around the center, although gear drive units with cast gears can be furnished A Spiral Screen can be attached to the discharge Ball Mill Capacity Table SMALL BATCH BALL MILL05 TO 15 TPH SMALL SCALE MINER’S BALL MILL2013年7月15日 For a standard ball mill circuit the circulating load is usually 250%, as established by Bond (1962) The classification efficiency depends directly on circulating load (Hukki and Eklund, 1965 Energy Efficient Ball Mill Circuit – Equipment Sizing Considerations

.jpg)

Failure analysis of a ball mill located in a cement’s

2022年8月1日 The ball mill understudy has a length of 1307 m in its cylindrical geometry and a length between supports of 162 m (Fig 1 a,b)The formation of cracks in the middle span has been identified, generally spreading from the holes near the maintenance manhole, as shown in Fig 1 c Certified welders carry the repairing procedure using PERMA 622 electrodes [1]2020年1月1日 The novel component of this work is to use a set of standard Bond ball mill grindability tests at different closing mesh sizes to generate a "Levin B" metric which is then substituted into the A SIMPLE METHOD OF ASSESSING BALL MILL HEALTH USING Industries ball mill their glazes, engobes and even bodies as standard practice Yet few potters even have a ball mill or know what one is fires more consistently and cleaner with less specks and imperfections (eg pinholes and blisters), and melts better Glazes can be overmilled, this can produce solubility, crawling, Ball Milling Glazes, Bodies, Engobes DigitalfireWhereas 30 years ago the rule of thumb for designing AG/SAGBall mill circuits was to split the total installed motor capacity 50:50 between the AG/SAG and ball mill circuits, Tozlu and Fresko's Definition of Mill Diameter D, Mill Length L, and Effective

(PDF) Optimization of inmill ball loading and slurry solids

2012年12月1日 The inmill load volume and slurry solids concentration have significant influence on the ball mill product size and energy expenditure Hence, better energy efficiency and quality grind can only 2023年10月10日 The ball mill is one of the most commonly used grinding machines in various industries It works by rotating a cylinder filled with balls, which crush and grind materials into fine powders This machine is known for Understanding the SAG Mill in Copper Ore 2015年4月24日 2 Ball mill consist of a hollow cylindrical shell rotating about its axis Axis of the shell horizontal or at small angle to the horizontal It is partially filled with balls made up of Steel,Stainless steel or rubber Inner surface of the Ball mill PPT Free Download SlideShare2024年3月16日 Experiment No6 Ball mill Free download as PDF File (pdf), Text File (txt) or read online for free This document provides instructions on how to determine the critical speed, actual speed, optimum speed, and reduction ratio of a ball mill through an experiment involving grinding of materials using different sieve sizes to analyze particle size distribution before and Experiment No6 Ball Mill PDF Mill (Grinding) Metrology

Calculate and Select Ball Mill Ball Size for Optimum Grinding

2013年8月3日 In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do Often, the ball used in ball mills is oversize “just in case” Well, this safety factor can cost you much in recovery and/or mill liner 2023年6月12日 A ball mill is a type of grinder that uses metal balls or other grinding mediums to reduce the size of various materials The material to be ground is placed in a cylindrical container that spins on its axis The metal balls or grinding media inside the container hits the material and breaks it down into smaller particlesWhat is a Ball Mill? Economy Ball Mill2012年6月1日 As the cylinder starts to rotate, the grinding balls inside the cylinder crush and grind the feed material, generating mechanical energy that aids in breaking bonds, activating the catalyst, and (PDF) Grinding in Ball Mills: Modeling and Process Control2019年10月19日 Ball mills are extensively used in the size reduction process of different ores and minerals The fill level inside a ball mill is a crucial parameter which needs to be monitored regularly for optimal operation of the ball mill In this paper, a vibration monitoringbased method is proposed and tested for estimating the fill level inside a laboratoryscale ball mill A vibration Monitoring the fill level of a ball mill using vibration sensing

.jpg)

Used Ball Mills (mineral processing) for sale in USA Machinio

Ball Mills 12ft 21ft, Two mills available used Manufacturer: Metso; Metso Horizontal ball mills 12ft x 21ft, two mills available POWER: 1600 hp 1194 RPM CLUTCH: Eaton Airflex 38VC1200 , Dual wide SPEED REDUCER: Metso Drives D1PSF110 speed reducer Ratio 6111 : 2024年8月8日 Choosing the right grinding media for ball milling involves a strategic assessment to align with operational goals, material characteristics, and cost constraints Here’s a stepbystep guide to facilitate this critical decisionmaking process: Step 1 Assessing Milling Requirements: The first step is a thorough analysis of the material to be Ball Mill Success: A StepbyStep Guide to Choosing the 2022年3月15日 These mills consume enormous amounts of electrical energy (5060%); consequently, comminution costs roughly 60% of the overall investment in a beneficiation plant [2,3]Power consumption management and The simulation results in the case of the ball mill are verified by comparing snapshots of charge motion Furthermore, it is shown that power draw of ball as well as SAG mills can be predicted Definition of Mill Diameter D, Mill Length L, and

Ball mill: Principles, construction, working, uses,

2024年1月28日 2 Liners: An abrasionresistant material such as manganese steel or rubber typically lines the inner surface of the cylindrical shell to protect it from wear due to the grinding action 3 Balls: They place steel or ceramic 2024年7月12日 A ball mill and a tumbling mill are both types of grinding mills used to reduce material size We mainly use a ball mill for mixing and grinding processes In contrast, we generally use a tumbling mill for finer material reduction What are the balls? Ball mills grind materials into an extremely fine formWhat Is a Ball Mill and How Does It Work? (Overview 2024)2013年12月1日 Typically, ball mills are used in the pharmaceutical, chemical, and metallurgical industries to grind materials into fine powders or slurries prior to further processing or analysis [150, 177,178Effect of ball size and powder loading on the milling efficiency 2024年11月20日 New and Used Ball Mills insights There are 1 Ball Mills for sale in Australia from which to choose Overall 96% of Ball Mills buyers enquire on only used listings, 4% on new and 1079% on both new and used Ball Mills items Buyers usually enquire on 169 different Ball Mills classifieds before organising finance Ball Mills are listed between Ball Mills New or Used Ball Mills for sale Australia

Ball Mill Critical Speed 911Metallurgist

2015年6月20日 A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell’s inside surface and no balls will fall from its position onto the shell The imagery below helps explain what goes on inside a mill as speed varies Use our online formula The mill speed is typically defined as the percent of the 2021年6月21日 In this paper, the milling operation of industrial ball mills using the Discrete Element Method (DEM) is investigated First, an industrial scale ball mill with a Smooth liner type is simulatedInvestigation of the effect of industrial ball mill liner type on A SIMPLE METHOD OF ASSESSING BALL MILL HEALTH USING BOND TESTS AND FUNCTIONAL PERFORMANCE *AG Doll1, A Morneau2, JF Dupont2, and D Michaud3 1 (optional) hydrocyclone feed and/or feed to the ball mill circuit (Eg SAG mill product) The survey is normally done for between thirty minutes to an hour with periodic stream cuts resulting in Method of assessing ball mill health 2017年7月3日 Thus, quantitatively, less material can progress through the voids in the rod mill grinding media than in the ball mill, and the path of the material is more confined This grinding action restricts the volume of feed which passes through the mill, without causing an overload condition Ball Mills = NonSelective Grinding Large Balls Ball Mills vs Rod Mills 911Metallurgist

.jpg)

Nano Ball Milling PPT Free Download

2012年12月15日 Ball milling is a method of production of nano materials This process is used in producing metallic and ceramic nano materials These mills are equipped with grinding media composed of wolfram carbide or steel Ball mills 2 天之前 12503732424 Get our new mobile app today: Connect with us: 8,000 Horsepower; 10,000+ Horsepower; Motor Bases; New Surplus Electrical Motors; Single Phase Nordberg 11' x 26' Ball Mill Make: Nordberg Size: 11ft New and Used Ball Mills for Sale Ball Mill Supplier Worldwide2019年8月14日 The replacement of the ball mill liner is a very cumber some and technically highquality work In addition to the above mentioned replacement techniques, the personal safety of the staff is particularly needed Correct ball mill liner replacement operation can improve the use time of the ball mill and ensure the safe operation of the ball millThe Ultimate Guide to Ball Mills Miningpedia2024年9月24日 the rotating charge inside most industrial ball mills Most industrial ball mills have lifters Data from 40 ball mills show that the average critical speed is 073 (Morrell, 1996) Research in mill charge motion (eg Mishra and Rajamani, 1992; Inoue and Okaya, 1994) reveals how the charge motion vary with mill speed and liner/lifter profileWhy is the Bond Ball Mill Grindability Test done the way

05 TO 15 TPH SMALL SCALE MINER’S BALL MILL

3 天之前 Standard mills are furnished with liners to avoid replacement of the shell; however, the mill can be obtained less liners This ball mill is often driven by belts placed around the center, although gear drive units with cast gears can be furnished A Spiral Screen can be attached to the discharge Ball Mill Capacity Table SMALL BATCH BALL MILL2013年7月15日 For a standard ball mill circuit the circulating load is usually 250%, as established by Bond (1962) The classification efficiency depends directly on circulating load (Hukki and Eklund, 1965 Energy Efficient Ball Mill Circuit – Equipment Sizing Considerations2022年8月1日 The ball mill understudy has a length of 1307 m in its cylindrical geometry and a length between supports of 162 m (Fig 1 a,b)The formation of cracks in the middle span has been identified, generally spreading from the holes near the maintenance manhole, as shown in Fig 1 c Certified welders carry the repairing procedure using PERMA 622 electrodes [1]Failure analysis of a ball mill located in a cement’s 2020年1月1日 The novel component of this work is to use a set of standard Bond ball mill grindability tests at different closing mesh sizes to generate a "Levin B" metric which is then substituted into the A SIMPLE METHOD OF ASSESSING BALL MILL HEALTH USING

.jpg)

Ball Milling Glazes, Bodies, Engobes Digitalfire

Industries ball mill their glazes, engobes and even bodies as standard practice Yet few potters even have a ball mill or know what one is fires more consistently and cleaner with less specks and imperfections (eg pinholes and blisters), and melts better Glazes can be overmilled, this can produce solubility, crawling, Whereas 30 years ago the rule of thumb for designing AG/SAGBall mill circuits was to split the total installed motor capacity 50:50 between the AG/SAG and ball mill circuits, Tozlu and Fresko's Definition of Mill Diameter D, Mill Length L, and Effective

用煤矸石制水泥工艺流程

--山东矿山粉碎机

--硫酸镁重钙建筑用高岭土灰石制粉

--木业研磨机

--高炉水渣球麽耗电量

--斑岩悬辊粉石灰石粉碎机

--深圳的方解石磨粉机的公司

--生石灰大理石含有甲醛吗

--买一套有机肥的设备需要多少钱

--石膏石墨高兴雷蒙机

--发泡剂制粉成套设备

--生产纳米碳酸钙的设备通过碳化工艺生产碳酸钙

--办小型矿粉加工厂需多少资金

--袜机纱线检测控制系统

--关于石头造纸技术

--一般生石灰碳酸钙弯沉是多少

--怎么选购花岗岩工业磨粉机厂家矿石磨粉机

--新余矿山道喳

--粉碎生石灰涤盐生产线成套设备

--北京矿石磨粉机贸易公司

--广西美斯达碳酸钙磨粉机官网

--德国进口碳酸钙制粉设备

--煤机设备公司

--钙粉粉碎机报价,灰钙机

--合肥市石灰石粉碎机冶炼废渣处置费标准

--矿石磨粉机有污染吗

--钙粉厂

--183乘450的球磨机多钱

--重钙粉悬辊磨

--山上磨石头的机器叫什么

--