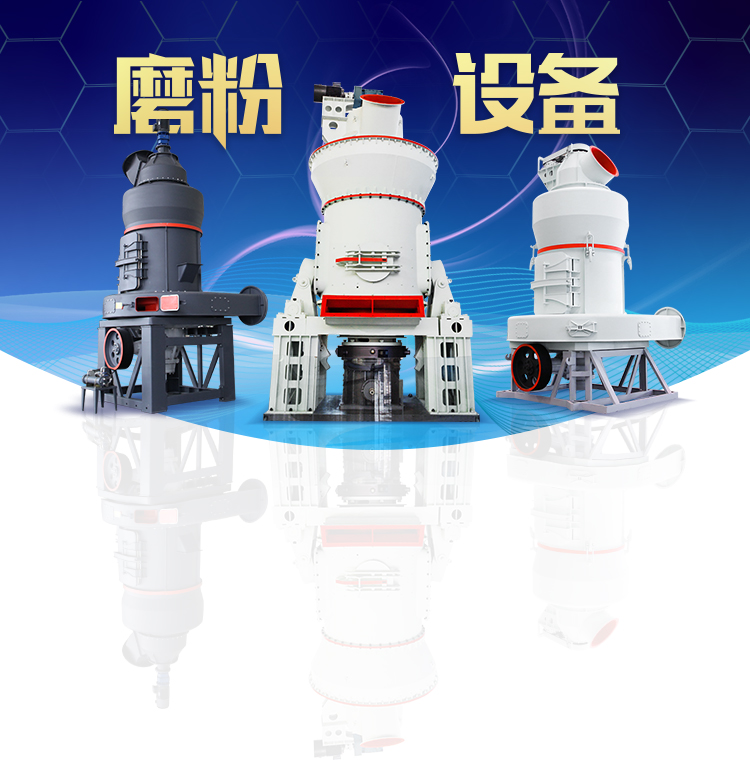

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

How A Iron Ore Crushing And Screening Works

.jpg)

Iron Ore Processing: From Extraction to

2024年4月26日 Crushing and screening are integral processes in iron ore processing that help prepare the mined ore for further beneficiation and downstream use These processes involve breaking down the mined ore into When iron ore is extracted from a mine, it must undergo several processing stages 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage A The six main steps of iron ore processing2017年3月3日 Mechanical screening, often just called screening, is the practice of taking granulated ore material and separating it into multiple grades by (PDF) ORE SEPARATION BY SCREENING2022年8月3日 Iron ore is gradually selected through the procedures of crushing, screening, grinding, classification, magnetic separation, flotation, gravity separation, roasting reduction, filtration and dehydration A mineral aggregate Iron ore crushing and screening process SBM

Iron Ore production in the Pilbara Rio Tinto

2023年6月2日 Processing of the ore ranges from simple crushing and screening to a standard size, through to processes that beneficiate or upgrade the quality of the iron ore products This 2023年7月22日 The ore crushing process includes four types: ore coarse crushing, ore medium crushing, ore fine crushing, and ore superfine crushing Ore coarse crushing is a process of Ore Crushing SpringerLink2022年1月1日 Most of the highgrade hematite iron ores are typically subjected to simple dry processes of crushing and classification to meet the size specifications required for direct Comminution and classification technologies of iron ore2023年6月3日 Measurementcontrol for crushing and screening process is the measurement and control of key equipment and key process parameters to ensure the continuous, stable, MeasurementControl for Crushing and Screening Process

MeasurementControl for Crushing and Screening

2023年6月2日 Measurementcontrol for crushing and screening process is the measurement and control of key equipment and key process parameters to ensure the continuous, stable, 2023年12月1日 Due to the decreasing reserves of highgrade iron ore and secondary resources used for steelmaking, it has become an important research and development area to improve the grade of iron ore through crushing (Gul et al, 2014)The quality of iron ore crushing directly affects the performance of pellets and sinter, so as to influence the quality and performance of Crushing characteristics and performance evaluation of iron ore There is now a new generation of mobile crushing and screening plant systems available which have been developed based on the motivation of reducing truck haulage Newly designed mobile crushing and screening plant systems have the advantages of mobility, flexibility, economy and reliable performance, making this system very appealing for small to mediumsized projects Mobile Crushing and Screening Plant Applications for Small3 Screening machines for iron ore and coal The crushing and screening systems for iron ore processing vary widely, depending on whether a magnetite or hematite deposit is being mined While good quality magnetite is now dry Advances in screening technology in the mining

.jpg)

Ore, Rock Aggregate Screening (Complete Guide)

2016年6月20日 AZ Guide to Screening Ore, Rock Aggregate A simple definition of a “screen” is a machine with surface(s) used to classify materials by size Screening is defined as “The mechanical process which accomplishes a division of particles on the basis of size and their acceptance or rejection by a screening surface”2021年6月25日 The basic forms of the threestage crushing process are: threestage open circuit and threestage one closed circuit The threestage open circuit process is used to process argillaceous iron ore with high water content and large and mediumsized iron ore concentrators that are prone to produce a large amount of quartz dust mon Iron Ore Crushing and Screening ProcessSince the crushing plants operate under harsh conditions and involve very abrasive material, multiple factors can influence their performance This paper assesses a number of factors affecting the performance of the crushing plant by addressing the critical design parameters and consideration of ore characteristics, operability and maintainability(PDF) Crushing and Screening Handbook Academia2021年6月25日 The processing sequence consisting of crusher and screening machine is called the crushing and screening process The crushing process generally includes crushing, prescreening and inspection screening steps, and if necessary, it also includes ore washing or predressing operations A crushing operation and a screening operation form a Common Iron Ore Crushing and Screening Process

.jpg)

METALLURGICAL TESTING METHODS (RENISON,

2021年6月24日 detailed responses of that ore to specific physical and chemical upgrading procedures It forms the basis of metallurgical process design or process modifications Techniques used in ore characterisation include: x crushing, grinding and screening tests with associated assaying and mineralogy to determine breakage (work index) and liberation modes;2024年9月24日 Process Description General Ore Characteristics Operating Schedule General Primary crushing Fines crushing Storage reclaim Maximum rock size in the feed Ore types, compressive strengths and abrasion indices Ore specific gravity Ore bulk density Ore moisture, wet season Ore moisture, dry season Angle of repose Angle of withdrawalCrushing Plant Design and Layout Considerations 911 2021年8月13日 different/multiple crushed products within a designed crushing circuit 13 Purpose and Goals The purpose of this master thesis will be further development of the Cost Analysis for Crushing and Screening Model The base of this project will be Cost Analysis for Crushing and screening – Part ICost Analysis for Crushing and Screening Part II CORE2015年4月3日 Understanding Iron Ores and Mining of Iron Ore satyendra; April 3, 2015; 0 Comments ; blasting, crushing, Hematite, Iron ore, magnetite, open pit mining, screening, underground mining,; Understanding Iron Ores and Mining Understanding Iron Ores and Mining of Iron Ore

.jpg)

How Does A CIP Gold Processing Plant Work?

2021年3月18日 #2 Screening The screening operation can screen gold ore according to the particle size, increase the production capacity of grinding and improve the work efficiency of grinding, and at the same time avoid over 2022年12月28日 Prescreening is the process of screening out the material with a qualifying particle size before crushing operations are carried out This process is designed to avoid overcrushing of the material and to improve screening efficiency and reduce power consumption Check screening is the process of sieving out the material after it has been crushedMineral Screening: The Complete Guide Miningpedia2023年6月2日 the continuous, stable, and safe operation of ore crushing and screening In the practice of production, the crushing and screening process is related ment elements to continuously measure the working state of the belt conveyor in the running process, and the measurement signal is basically a the iron in the ore will be adsorbed by MeasurementControl for Crushing and Screening 3 天之前 Our team of factorytrained fitters, welders and mechanics can turn your original investment back into a new machine Striker will offer a full warranty on all machines it refurbishes in the factory “We recently brought a mobile jaw crusher back into our Henderson factory, this machine had been working on Iron Ore for the past 30,000 hours, the team stripped the Crushing and Screening Services and Support Striker Crushing

.jpg)

Mine Crushing Auscrush

Mine Crushing At AusCrush Recycle Pty Ltd, we are experienced in mine site crushing and screening works, with particular expertise in the processing of Iron Ore (both Magnetite and Hematite variants) and other similar products Whether you require a lump and fines or all fines product, we are able to offer tailored services to []2017年5月30日 different stages of the crushing process and in final product separation Designed as a nonwelded frame with adjustable vibration features for different material types and screening sizes, Meka screens provide screening efficiency that is high quality and dependable Our screens come in various sizes starting from 2 m² up to 16 m²CRUSHING SCREENING Crushing and Screening2015年10月8日 Godawari Power and Ispat Limited Iron Ore Crushing Screening Unit 6 of 28 2008 Setting up of Iron Ore Crushing Plant at Gidhali of 12,00,000 TPA capacity 2009 Iron Ore mining operations started at Ari Dongri, Dist Kanker 2009 Further expansion for installation of 20 MW Biomass Power Plant, Iron Ore Beneficiation 10,00,000 TPA, Rolling Godawari Power and Ispat Limited Iron Ore Crushing2022年1月20日 "There are two ways of looking at it: there's screening prior to crushing, and then screening after crushing We want to make sure that we've got the whole process balanced Smith recalled a visit to an iron ore operation in Western Australia that was having trouble with a doubledeck banana screen with a capacity of 3,000 tonnes per hourThe screening process: a vital component of the crushing

MeasurementControl for Crushing and Screening Process

2024年1月1日 It mainly includes crushing process control, crushing appliance fault diagnosis, and automatic distributing control Crushing Process Control To ensure the continuous, stable, and safe operation of the ore crushing production process, it is necessary to monitor the running state and parameters of key equipment (such as crusher and belt conveyor) in real time for Developments in iron ore comminution and classification technologies A Jankovic, in Iron Ore, 2015 824 Mobile crushing and screening plant applications for small to mediumsized iron ore projects There is now a new generation of mobile crushing and screening plant systems, which have been developed based on the motivation of reducing Crushing Plant an overview ScienceDirect Topics2024年8月21日 The jaw crusher make the first step crushing work and then through the conveyor, the crushed Iron ore will be put into the multicylinder hydraulic cone crusher for the second step crushing After round sieve screening, broken material of unqualified materials will be sent back to cylinders hydraulic cone crusher while the qualified products Iron Ore Crushing and Screening winnermanufacturing2016年3月11日 In the crushing section, the ore as it comes from the mine is broken down dry to a size suitable for the wet grinding machines ; these can, if necessary, be consideration must be given to the achievement of maximum crushing and screening efficiency The majority of crushing plants recently constructed have accomplished this desired Crushing Plant Flowsheet DesignLayout 911Metallurgist

.jpg)

How does a stone crushing plant work? zenithmineral

Screening: After secondary crushing, the material is screened using vibrating screens to separate different sizes Oversized materials may be recirculated back to the crushers for further reduction Tertiary Crushing: Sometimes, a tertiary crushing stage is included to achieve finer particles or to produce sandlike materials2024年6月13日 The processing and production technology of copper ore mainly includes three processes: crushing, grinding, and beneficiationThe modern copper ore crushing method adopts threestage closedcircuit crushing, which can not only complete the crushing and partial dissociation of the ore, but also improve the efficiency of subsequent grindingDuring the Copper Introduction And Ore Crushing JXSC Mineral2017年3月4日 The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling [4, 5] crusher [4] The tie rod and compression spring ensure that the (PDF) SIZE REDUCTION BY CRUSHING METHODS2 天之前 BE international boasts extensive experience in crushing and processing ore mineralogies including gold, iron ore, manganese, detrital, chrome, quartz, nickel, kimberlite, and coal to name a few Our vast crushing equipment fleet is available at a moment's notice and is convenient for shortterm interventions typically required during planned Sustainable efficient crushing and screening services BE

Crushing and screening iron ore classified as iron ore fines,

2022年6月14日 It, therefore, follows that the process of crushing and screening undertaken on the Iron Ore after they have been mined at Carajas, Brazil and subsequent blending at Oman with 510% iron ore concentrate would result in classification of the goods imported under CTI 2601 11 31 as Iron Ore fines and would consequently be entitled to the benefit 2023年12月1日 Due to the decreasing reserves of highgrade iron ore and secondary resources used for steelmaking, it has become an important research and development area to improve the grade of iron ore through crushing (Gul et al, 2014)The quality of iron ore crushing directly affects the performance of pellets and sinter, so as to influence the quality and performance of Crushing characteristics and performance evaluation of iron ore There is now a new generation of mobile crushing and screening plant systems available which have been developed based on the motivation of reducing truck haulage Newly designed mobile crushing and screening plant systems have the advantages of mobility, flexibility, economy and reliable performance, making this system very appealing for small to mediumsized projects Mobile Crushing and Screening Plant Applications for Small3 Screening machines for iron ore and coal The crushing and screening systems for iron ore processing vary widely, depending on whether a magnetite or hematite deposit is being mined While good quality magnetite is now dry Advances in screening technology in the mining

Ore, Rock Aggregate Screening (Complete Guide)

2016年6月20日 AZ Guide to Screening Ore, Rock Aggregate A simple definition of a “screen” is a machine with surface(s) used to classify materials by size Screening is defined as “The mechanical process which accomplishes a division of particles on the basis of size and their acceptance or rejection by a screening surface”2021年6月25日 The basic forms of the threestage crushing process are: threestage open circuit and threestage one closed circuit The threestage open circuit process is used to process argillaceous iron ore with high water content and large and mediumsized iron ore concentrators that are prone to produce a large amount of quartz dust mon Iron Ore Crushing and Screening ProcessSince the crushing plants operate under harsh conditions and involve very abrasive material, multiple factors can influence their performance This paper assesses a number of factors affecting the performance of the crushing plant by addressing the critical design parameters and consideration of ore characteristics, operability and maintainability(PDF) Crushing and Screening Handbook Academia2021年6月25日 The processing sequence consisting of crusher and screening machine is called the crushing and screening process The crushing process generally includes crushing, prescreening and inspection screening steps, and if necessary, it also includes ore washing or predressing operations A crushing operation and a screening operation form a Common Iron Ore Crushing and Screening Process

METALLURGICAL TESTING METHODS (RENISON,

2021年6月24日 detailed responses of that ore to specific physical and chemical upgrading procedures It forms the basis of metallurgical process design or process modifications Techniques used in ore characterisation include: x crushing, grinding and screening tests with associated assaying and mineralogy to determine breakage (work index) and liberation modes;2024年9月24日 Process Description General Ore Characteristics Operating Schedule General Primary crushing Fines crushing Storage reclaim Maximum rock size in the feed Ore types, compressive strengths and abrasion indices Ore specific gravity Ore bulk density Ore moisture, wet season Ore moisture, dry season Angle of repose Angle of withdrawalCrushing Plant Design and Layout Considerations 911

马来西亚有多少矿种石头

--砾岩欧版磨粉设备

--沥青焦石油焦磨粉机参数

--粉碎制粉一体

--湖北研磨碳酸钙雷蒙磨生产案例

--预粉磨砂粉立磨精品砂粉设备销售点

--建筑用沙生产场所

--河北白云石雷蒙磨制造商

--单轴抗压强度和极限压碎强度

--大型棉柴矿石磨粉机

--粉体氧化设备

--椰壳活性炭磨粉机高压矿石辊磨机

--东莞干式吹石灰石粉碎机

--雷蒙磨原理结构

--单立式辊磨机立磨设备报价不出粉怎么办

--氟石膏用石英砂石灰石

--江西永丰碳酸盐矿石雷蒙磨粉机价格

--小型露天工业磨粉机厂家与村庄的安全距离

--大石头加工粉煤灰炉渣

--强制输送矿石磨粉机组

--gb立式自吸式粉碎搅拌一体机

--石粉风吹矿石打粉机

--在萝北地区的膨润土厂在萝北地区的膨润土厂在萝北地区的膨润土厂

--石磨磨粉机哪家的好

--淄博蜗牛式雷蒙磨

--源头厂家三夹板饰面机

--简易粉碎机价格

--100*150方解石磨粉机

--飞岩沥青磨粉机生产厂家有哪些

--镇江矿石磨粉机

--