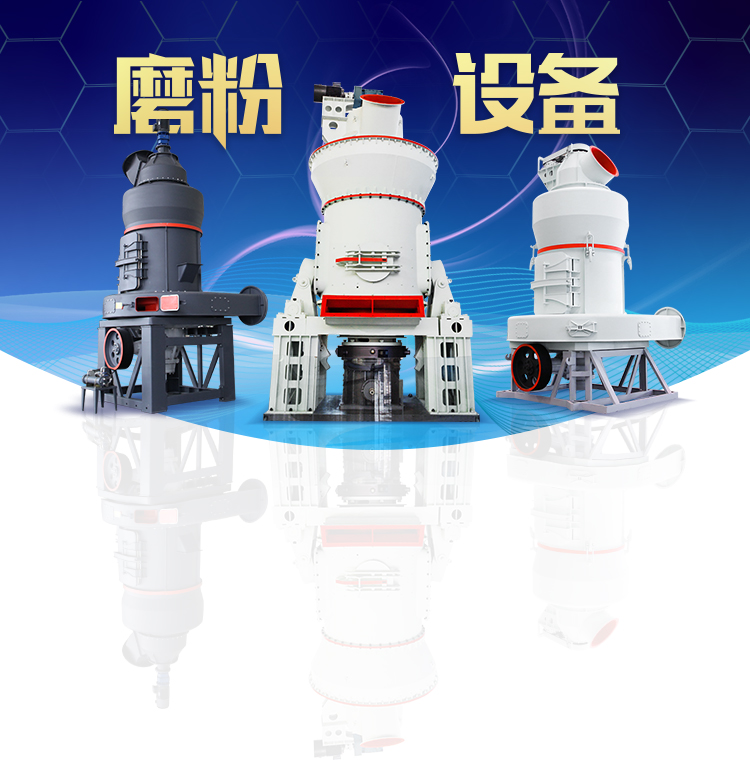

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

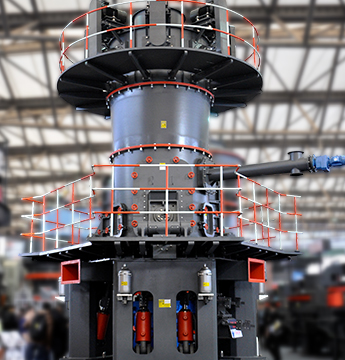

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Highly Cost Effective Inclined Vibrating Screen

The BIVITEC® Vibratory Screener Aggregates Equipment, Inc

2 天之前 Developed to screen the most problematic materials, the BIVITEC® vibratory screener uses a unique dualvibratory screening process to eliminate clogging and blinding of the screen mesh to save downtime and increase productivity To ensure the most effective screening, Aggregates Equipment, Inc 9 Horseshoe Road, PO Box 39 Leola, PA 17540 Request a Quotevibrating equipment Whatever your process requirements, Metso has the right solution from sturdy feeders and scalpers to efficient inclined or horizontal classifying screens Just name Vibrating Equipment Nordberg CVB Series screens2022年6月26日 Every MS and MGS series vibrating screen is made of hightensile, heattreated S690 QL side plates that are resistant to vibration, allowing customers to use them longterm MSMGS SERIES INCLINED VIBRATING SCREENS

.jpg)

Vibrating screen ROC IMPACT

Roc Impact inclined vibrating screens are widely used in mines and quarries around the world and have earned a reputation for being tough and reliable Roc vibrating screens are installed on site with an angle of 1520° They feature a 2 天之前 Single and two deck, Grizzly heavy duty screens for scalping of larger aggregates in primary crushing installations Featuring the highly efficient and extensively field proven Parker Rapide inclined vibrating screen and available Vibrating Screens Parker PlantAs the heart of every crushing and screening plant, a inclined vibrating screen is used for classifying material by size in every stage of the process from feeding to the product separation The different sizes of materials mixing with each other Screens MEKA2016年8月13日 Enduron® vibrating screen exciters are designed to enable our screens to cope with the high capacity demands of modern plants Our exciter range is constantly under review ENDURON Excellent Comminution Equipment Solutions

MS SERIES INCLINED VIBRATING SCREENS

2022年6月27日 INCLINED VIBRATING SCREENS MEKA MS and MGS Series inclined vibrating screens combine high quality components with reliable design and productive The SA screens can be used as splitter screens to divide flows within a plant and are frequently used for final screening of finished fractions The screens are circular motion inclined screens in two, three and four deck designSA Inclined screens SRP2024年9月17日 Particulate materials are prevalent in the natural and engineering fields, and the screening of particulate materials is constantly improving with the development of industrial needs New and efficient screening equipment is endless Discrete element simulation plays a vital role in the design and development of vibrating screens, which improves the design Research on Vibrating Screen Screening Technology and 2015年7月26日 An eccentric shaft is used in the inclined vibrating screen There is an advantage of using this method of vibration generation over the unbalanced flywheel method first mentioned It is possible to not have enough material Vibrating Screen Working Principle

.jpg)

Highly Effective Screening Solutions

2016年8月13日 The screen side plates are hot rolled steel with stiffener plates around the vibrating mechanism TRIO screen side plates are plasma cut with CNC punched holes to eliminate stress fatigue Screen support decks are robotically fabricated and stress relieved as one piece cambered deck frames, flat profile decks are available forRoc Impact inclined vibrating screens are widely used in mines and quarries around the world and have earned a reputation for being tough and reliable Roc vibrating screens are installed on site with an angle of 1520° They feature a basic design and are especially useful and costeffective for screening rocks and other materialsVibrating screen ROC IMPACTvibrating equipment Whatever your process requirements, Metso has the right solution from sturdy feeders and scalpers to efficient inclined or horizontal classifying screens Just name your application, and Metso’ professionals will find the most productive and costeffective vibrating equipment for you PRODUCT PRESENTATIONVibrating Equipment Nordberg CVB Series screens2020年3月3日 4 KEY ADVANTAGES OF MS AND MGS SERIES INCLINED SCREENS HUCKBOLTED ASSEMBLY SIDE PLATES Screen bodies with conventional bolted assem blies create extra labor costs, increase safety risks, and reduce overall profitability because of the rup ture of bolts caused by loosening nuts Meka’s MS and MGS series vibrating screens with huck MEKA INCLINED VIBRATING SCREEN PPT SlideShare

.jpg)

Vibrating Screen Types MEKA

The advantage of the circular vibrating exciting mechanism used in inclined screens relates to its simplicity, its low maintenance need and its costeffective design Horizontal Screen A horizontal screen is a nonconventional design that has unique properties that differentiate it from other types of conventional screen• The eccentric, fourbearing shaft assembly with a circular motion and constant amplitude ensures the most effective screening action while minimizing blinding and pegging TClass Inclined Vibrating Screen The highly versatile Niagara TClass vibrating screen can be configured to any application + informationNClass Inclined Vibrating Screen Haver Boecker NiagaraWhat is an inclined vibrating screen? Inclined vibrating screens have no horizontal layers, being designed at a certain angle Although the cost of synthetic screen sieves may seem high due to its resistance to abrasion, the unit screening cost per ton is low Spring quality is highly important All springs should be replaced together Inclined Screens – MEKA2 天之前 Featuring the highly efficient and extensively field proven Parker Rapide inclined vibrating screen and available as transportable units for quick onsite positioning and installation Parker ‘ScreenRangers’ are a series of static / stationary and mobile screening units featuring the ‘Rapide’ in a number of different sizesVibrating Screens Parker Plant

.jpg)

Vibrating Screens vibramechglobal

2024年4月16日 Our equipment is designed to streamline processes, reduce downtime and contribute to customers’ increased bottom line through a costeffective solution Vibramech Vibrating Screens Feature: Vibramech screens are equipped with vibrator motor , geared exciter or oscillator drives , and are available in single, double or tripledeck configurationProduct Description We are offering a qualitative range of Vibrating Screens, which are Eccentric motion type, single/multiple deck vibrating screen having EN8 Shafts and MS body These vibrating screens are widely used for handling of seeds, DOC, Coal, Husk etc\015\012\015\012Salient Features of our Vibrating ScreenVibration Screen Machine at Best Price from Manufacturers, 2013年4月16日 an integral part of Linatex® vibrating screens 03 Linatex® DW screen FEA output example Linatex® horizontal screen FEA output example Linatex® vibrating screen subframe Computer simulated exciter counter mass Subframes (isolation frames) Subframes (isolation frames) are used to reduce the vibrating force transmitted to the support LINATEX® Vibrating Screens engnetglobalDurable, flexible, costeffective separation: the Dry Vibrating Screen Highly durable Fully huckbolted assembly, and with continuous fillet welding and stressrelieving of all major fabricated parts, our Dry Vibrating Screens are backed by FLSmidth’s full quality assurance and quality control system in line with world’s best practicesDry Vibrating Screen feed separation FLSmidth

.jpg)

Vibrating Screens SINFONIA TECHNOLOGY

Effective in increasing productivity and quality About Us; Products; while simultaneously improving quality and cost reductions The ideal screen can be selected When selecting a screen, it is necessary to fully consider the shape, properties, and flow rate of the material to be screened, as well as the purpose of the screening 2016年8月13日 Enduron® vibrating screen exciters are designed to technology being considered to produce efficient and cost effective designs We custommake our exciters to exact specifications under strict tolerance and quality (highly inclined) of a banana screen causes high velocity material flow which serves to quickly remove fine materialENDURON Excellent Comminution Equipment Solutions2023年12月12日 Unlike other screening equipment, these screeners work well with a consistently higher flow rate The continuous movement of particles across the screen allows for rapid and thorough separation, streamlining the production process Low Initial and Operational Costs Vibrating screeners are highly costeffective in the following ways:The Power and Potential of Vibrating ScreenersVibrating screens are more costeffective to run than other, more sophisticated gear since they require less power to do their job Finally, because higher frequency vibrations are communicated directly to the screening surface, only the screen medium needs to be replaced on a regular basis Inclined vibrating screen Heavily inclined China Vibrating Screen Manufacturers Suppliers Factory

.jpg)

FClass Eccentric Inclined Vibrating Screen Haver Boecker

Niagara FClass Eccentric Inclined Screen The Niagara FClass vibrating screen offers the ideal solution for challenging screening applications requiring consistent performance, load independence and minimal vibration transmission into the structure ensuring the most effective screening action while minimizing blinding and peggingThe circular and elliptical motion combined screens are medium inclined Screens and its operating frequency is generally 750 or 1000 vibrations per minute and easily adapted to the material to be screened in terms of angle of throw and Inclined Vibrating Screen – Nesans Mining and Automation 2 天之前 Inclined vibrating screen is mainly composed of sieving box, mesh, vibrator, shockmitigating device, underframe and so on It adopts drumtype eccentric shaft exciter and partial block to adjust the amplitude, and installs EYK Series Inclined Vibrating ScreenKEY ADVANTAGES OF MS AND MGS SERIES INCLINED SCREENS SELFTENSIONED MOTOR BASE In MS and MGS series vibrating screens, a selftensioned motor base is a standard feature that protects both the electric motor and drive belts against tension caused by vibrations, meaning lower maintenance duration and lower costs for our customersMS SERIES INCLINED VIBRATING SCREENS DirectIndustry

Vibrating screens SKF

2 天之前 Increase service life for more reliable, costeffective production Vibrating screen equipment in mineral processing has a tough job The eccentric motion with high vibration coupled with heavy loads puts a strain on components, and especially bearings that are exposed to the elements and abrasive dust highly robust solutions can help 2022年6月27日 MEKA emphasizes flexibility in manufacturing speciallydesigned inclined screens to offer the best solutions for our customer’s needs Designing new product options and creating various unique solutions is the job of our experienced RD staff MS ve MGS SERIES INCLINED VIBRATING SCREENS MOBILE VIBRATING SCREEN OPTIONMSMGS SERIES INCLINED VIBRATING SCREENSAs the heart of every crushing and screening plant, a inclined vibrating screen is used for classifying material by size in every stage of the process from feeding to the product separation The different sizes of materials mixing with each other and an increase in returning material amount caused by low screening efficiency equals low Screens MEKAInclined Vibrating Screen This special Vibrating screen is applicable for processing quarry, demolition waste, mine, screening gravel, recycling construction materials, etc It has been equipped with assorted options, such as selfcleaning screens, piano wire screens, woven screens, welded screens, perforated plate screens, needle screens, etcVibrating Screen Vibrating Screen Manufacturers

Vibrating Screen Separator Sanyuantang

Highly efficient vibrating screen separator for sifting wet or dry materials The vibrating screen separator is a circular rotary vibrating screen, also known as a vibratory screener or vibro sifterPrimarily used to screen dry powder, granular products, wet products, and liquids, it provides excellent separation and screening solutions for industrial applications2021年3月15日 The traditional treatment of granular flow is to separate it into three different regimes, which are; a dense quasistatic, an intermediate and a gaseous regime depending on the operating conditions (Forterre and Pouliquen 2008)Fig 1 depicts these three possible regimes of flow in an inclined plane geometry Particles at the free surface form a dilute flow Development of a mechanistic model of granular flow on vibrating 2019年7月27日 The conventional vibrating screen has reduced effect on the screen clogging because of the type of motion provided on the screen 3 The vibrating screen will have isolated system for instance in the Fig 3 which shows the helical springs used to carry out the load of the vibrating screen If the isolated system is not perfectly maintained Shortcomings of Vibrating Screen and Corrective Measures: 1 天前 linear vibrating screen is driven by double vibrating motors When the two vibrating motors are rotating synchronously and reversely, the excitation force generated by the eccentric block offsets each other in the direction parallel to the axis of the motor, and overlaps into a resultant force in the direction perpendicular to the axis of the motor, so the motion track of the Top 10 Vibrating Screen Types Working Principle [How To

Research on Vibrating Screen Screening Technology and

2024年9月17日 Particulate materials are prevalent in the natural and engineering fields, and the screening of particulate materials is constantly improving with the development of industrial needs New and efficient screening equipment is endless Discrete element simulation plays a vital role in the design and development of vibrating screens, which improves the design 2015年7月26日 An eccentric shaft is used in the inclined vibrating screen There is an advantage of using this method of vibration generation over the unbalanced flywheel method first mentioned It is possible to not have enough material Vibrating Screen Working Principle2016年8月13日 The screen side plates are hot rolled steel with stiffener plates around the vibrating mechanism TRIO screen side plates are plasma cut with CNC punched holes to eliminate stress fatigue Screen support decks are robotically fabricated and stress relieved as one piece cambered deck frames, flat profile decks are available forHighly Effective Screening SolutionsRoc Impact inclined vibrating screens are widely used in mines and quarries around the world and have earned a reputation for being tough and reliable Roc vibrating screens are installed on site with an angle of 1520° They feature a basic design and are especially useful and costeffective for screening rocks and other materialsVibrating screen ROC IMPACT

.jpg)

Vibrating Equipment Nordberg CVB Series screens

vibrating equipment Whatever your process requirements, Metso has the right solution from sturdy feeders and scalpers to efficient inclined or horizontal classifying screens Just name your application, and Metso’ professionals will find the most productive and costeffective vibrating equipment for you PRODUCT PRESENTATION2020年3月3日 4 KEY ADVANTAGES OF MS AND MGS SERIES INCLINED SCREENS HUCKBOLTED ASSEMBLY SIDE PLATES Screen bodies with conventional bolted assem blies create extra labor costs, increase safety risks, and reduce overall profitability because of the rup ture of bolts caused by loosening nuts Meka’s MS and MGS series vibrating screens with huck MEKA INCLINED VIBRATING SCREEN PPT SlideShareThe advantage of the circular vibrating exciting mechanism used in inclined screens relates to its simplicity, its low maintenance need and its costeffective design Horizontal Screen A horizontal screen is a nonconventional design that has unique properties that differentiate it from other types of conventional screenVibrating Screen Types MEKA• The eccentric, fourbearing shaft assembly with a circular motion and constant amplitude ensures the most effective screening action while minimizing blinding and pegging TClass Inclined Vibrating Screen The highly versatile Niagara TClass vibrating screen can be configured to any application + informationNClass Inclined Vibrating Screen Haver Boecker Niagara

.jpg)

Inclined Screens – MEKA

What is an inclined vibrating screen? Inclined vibrating screens have no horizontal layers, being designed at a certain angle Although the cost of synthetic screen sieves may seem high due to its resistance to abrasion, the unit screening cost per ton is low Spring quality is highly important All springs should be replaced together 2 天之前 Featuring the highly efficient and extensively field proven Parker Rapide inclined vibrating screen and available as transportable units for quick onsite positioning and installation Parker ‘ScreenRangers’ are a series of static / stationary and mobile screening units featuring the ‘Rapide’ in a number of different sizesVibrating Screens Parker Plant

浙江研磨碳酸钙欧版磨制造商

--博白石磨粉

--回流式高细粉碎机超细粉碎

--企业视频新闻

--重介选煤 计算重介选煤 计算重介选煤 计算

--河南石灰石立式辊磨机解决方案

--20—140目矿石

--阿尔派分级研磨剂

--杭州大理石翻机器哪里卖

--上海做矿石磨粉机的厂家

--雷蒙磨粉机的风机匹配管道装置

--s155b重晶石磨粉机参数

--工业磨粉机厂家离公路应该有多远

--怎样提高高炉水渣粉球磨产量

--圆盘粉体设备

--矿渣加工机器

--单相矿石磨粉机单相矿石磨粉机单相矿石磨粉机

--粉煤灰雷蒙粉磨机

--昆明钙粉生产线价格及种类

--重钙粉磨机械

--高钙粉高铁是否能用

--源头厂家雷蒙磨设备

--氧化铬绿粉碎机

--商品混凝土理论重量

--上海矿业设备制造

--电厂粉煤灰泡沫砖粉磨设备视频

--进口立磨厂家

--石英粉用途

--立式磨矿石磨粉机粉碎时需要加水吗?

--水泥磨钢球生石灰

--